Featured Products

-

Y-Type Strainer 150LB API609 Casting iron Ductile iron Filter Stainless Steel Strainers

Size:DN 50~DN 300

Pressure:150 psi/200 psi -

API609 Y-Type Strainer body in Casting iron Ductile iron Filter in Stainless Steel 304

Size:DN 50~DN 300

Pressure:150 psi/200 psi -

Y-Type Flange Strainer PN10/16 API609 Casting iron Ductile iron GGG40 Filter in Stainless Steel

Size:DN 50~DN 300

Pressure:150 psi/200 psi -

Y-Type Strainer PN10/16 API609 Casting iron Ductile iron Filter in Stainless Steel

Size:DN 50~DN 300

Pressure:150 psi/200 psi -

API609 Y-Type Strainer body in Casting iron Ductile iron GGG40 Filter in Stainless Steel 304

Size:DN 50~DN 300

Pressure:150 psi/200 psi -

DN150 New desiged Backflow Preventer Ductile Iron Valve apply for water or wastewater

Water control combination device developed by TWS Valve;

Size:DN 50~DN 400

Pressure:PN10/PN16/150 psi/200 psi -

DN100 PN10 PN16 Backflow Preventer Ductile Iron GGG40 Valve apply for water or wastewater

Water control combination device developed by TWS Valve;

Size:DN 50~DN 400

Pressure:PN10/PN16/150 psi/200 psi -

DN150 pn10/16 Backflow Preventer Ductile Iron Valve apply for water or wastewater

Water control combination device developed by TWS Valve;

Size:DN 50~DN 400

Pressure:PN10/PN16/150 psi/200 psi -

DN150 PN10 PN16 Backflow Preventer Ductile Iron GGG40 Valve apply for water or wastewater

Water control combination device developed by TWS Valve;

Size:DN 50~DN 400

Pressure:PN10/PN16/150 psi/200 psi -

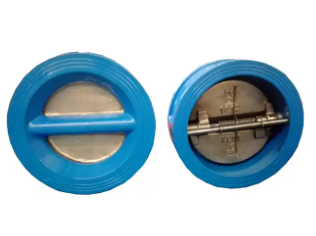

Wafer dual plate check Valve DN200 cast iron dual plate cf8 wafer check valve

Our crew through skilled training. Skilled expert knowledge, solid sense of service, to meet the service needs of customers for Chinese wholesale Good Quality Dual Plate Wafer Check Valve, Our solutions are widely recognized and reliable by users and can satisfy continuously acquiring economic and social needs.

Chinese wholesale China Valve and Check Valve, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our merchandise. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed. -

Ductile Iron Stainless Steel PTFE Material Gear Operation Splite type wafer Butterfly Valve

FD Series is PTFE lined and split-body type.

Size Range:DN 40~DN300

Pressure:PN10/150 psi -

New designed Balance Valve Casting Ductile Iron Bellows Type Safety Valve

Size:DN 50~DN 350

Pressure:PN10/PN16