Hot Selling Air Release Valve Well-designed Flange Type Ductile Iron PN10/16 Air Release Valve

We’ve got the most highly developed manufacturing machines, experienced and qualified engineers and workers, acknowledged good quality management systems and also a friendly specialist gross sales team pre/after-sales support for Well-designed Flange Type Ductile Iron PN10/16 Air Release Valve, To improved expand market, we sincerely invite ambitious individuals and providers to hitch as an agent.

We’ve got the most highly developed manufacturing machines, experienced and qualified engineers and workers, acknowledged good quality management systems and also a friendly specialist gross sales team pre/after-sales support for Air Release Valve, We always insist on the management tenet of “Quality is First, Technology is Basis, Honesty and Innovation”.We’re able to develop new products continuously to a higher level to satisfy different needs of customers.

Description:

Introducing Innovative High-Speed Exhaust Valve – Improving Efficiency and Performance

We are pleased to launch our latest product, the Air Release Valve, designed to revolutionize the way air is released in pipes and ensure optimal efficiency and performance. This high-velocity exhaust valve is the ultimate solution for eliminating air pockets, preventing air locks, and maintaining consistent flow.

Our vent valves are engineered with cutting-edge technology and precision to meet the needs of various industries including water supply, wastewater treatment and irrigation systems. Its superior functionality, durability and ease of installation make it the first choice of plumbing professionals worldwide.

Key features and benefits of our exhaust valves include:

1. Fast and effective air release: With its high-speed capability, this valve ensures rapid release of air pockets, preventing system flow obstruction and potential damage. Rapid air release feature improves overall system performance.

2. Superior Design: Our exhaust valves feature a well-designed mechanism that effectively eliminates air, reduces water hammer events, and increases the service life of your piping system. The high-quality materials used guarantee excellent durability and corrosion resistance.

3. Easy installation: The exhaust valve is designed for easy installation and maintenance. Its ergonomic design integrates seamlessly into existing piping, while simple operation ensures smooth operation without the need for special tools or extensive training.

4. Wide range of applications: Air release valves are suitable for various pipeline systems, including water treatment plants, sewage pipe networks, and even irrigation systems. Regardless of the application, this valve is designed to provide optimal performance and reliability.

5. Cost-effective solution: By integrating our vent valves into your duct system, you can significantly reduce maintenance costs, increase energy efficiency, and minimize unforeseen downtime. Its innovative design makes it a long-term investment, ensuring smooth operation for years to come.

All in all, our vent valves set new standards in cavitation elimination and duct efficiency. Experience the benefits of this innovative breakthrough technology and transform the performance of your piping system. Trust our commitment to quality, reliability and customer satisfaction. Upgrade to our high-velocity exhaust valves today and enjoy a seamless, efficient, high-performance piping system.

Performance requirements:

Low pressure air release valve (float + float type) the big exhaust port ensures that the air enters and exits at a high flow rate at a high speed discharged airflow, even the high-speed airflow mixed with water mist,It will not close the exhaust port in advance .The air port will only be closed after the air has been completely discharged.

At any time, as long as the internal pressure of the system is lower than the atmospheric pressure, for example, when the water column separation occurs, the air valve will immediately open to air into the system to prevent the generation of vacuum in the system. At the same time, timely intake of air when the system is emptying can speed up the emptying speed. The top of the exhaust valve is equipped with an anti-irritating plate to smooth the exhaust process, which can prevent pressure fluctuations or other destructive phenomena.

The high-pressure trace exhaust valve can discharge the air accumulated at high points in the system in time when the system is under pressure to avoid the following phenomena that may cause harm to the system: air lock or air blockage.

Increasing the head loss of the system reduces the flow rate and even in extreme cases can lead to a complete interruption of fluid delivery. Intensify cavitation damage, accelerate the corrosion of metal parts, increase pressure fluctuations in the system, increase metering equipment errors, and gas explosions. Improve the water supply efficiency of pipeline operation.

Working principle:

Working process of combined air valve when empty pipe is filled with water:

1. Drain the air in the pipe to make the water filling proceed smoothly.

2. After the air in the pipeline is emptied, the water enters the low-pressure intake and exhaust valve, and the float is lifted by the buoyancy to seal the intake and exhaust ports.

3. The air released from the water during the water delivery process will be collected in the high point of the system, that is, in the air valve to replace the original water in the valve body.

4. With the accumulation of air, the liquid level in the high-pressure micro automatic exhaust valve drops, and the float ball also drops, pulling the diaphragm to seal, opening the exhaust port, and venting the air.

5. After the air is released, water enters into the high-pressure micro-automatic exhaust valve again, floats the floating ball, and seals the exhaust port.

When the system is running, the above 3, 4, 5 steps will continue to cycle

The working process of the combined air valve when the pressure in the system is low pressure and atmospheric pressure (generating negative pressure):

1. The floating ball of the low pressure intake and exhaust valve will immediately drop to open the intake and exhaust ports.

2. Air enters the system from this point to eliminate negative pressure and protect the system.

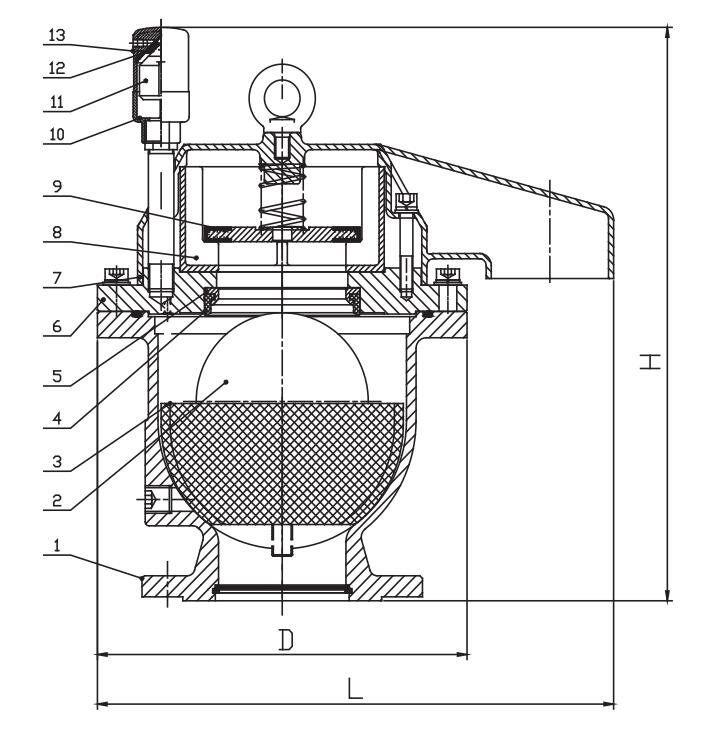

Dimensions:

| Product Type | TWS-GPQW4X-16Q | |||||

| DN(mm) | DN50 | DN80 | DN100 | DN150 | DN200 | |

| Dimension(mm) | D | 220 | 248 | 290 | 350 | 400 |

| L | 287 | 339 | 405 | 500 | 580 | |

| H | 330 | 385 | 435 | 518 | 585 | |

We’ve got the most highly developed manufacturing machines, experienced and qualified engineers and workers, acknowledged good quality management systems and also a friendly specialist gross sales team pre/after-sales support for Well-designed Flange Type Ductile Iron PN10/16 Air Release Valve, To improved expand market, we sincerely invite ambitious individuals and providers to hitch as an agent.

Well-designed Air Release Valve, We always insist on the management tenet of “Quality is First, Technology is Basis, Honesty and Innovation”.We’re able to develop new products continuously to a higher level to satisfy different needs of customers.