Manufactur standard Vertical Check Valve - EH Series Dual plate wafer check valve – TWS Valve

Manufactur standard Vertical Check Valve - EH Series Dual plate wafer check valve – TWS Valve Detail:

Description:

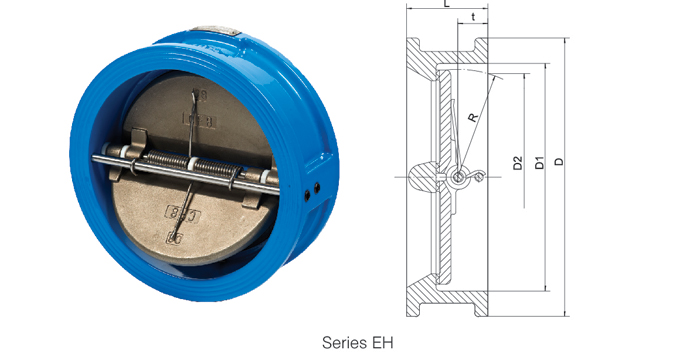

EH Series Dual plate wafer check valve is with two torsion springs added to each of pair valve plates, which close the plates quickly and automatically, that can prevent the medium from flowing back.The check valve can be installed on both horizontal and vertical direction pipelines.

Characteristic:

-Small in size, light in weight, compact in sturcture, easy in maintenance.

-Two torsion springs are added to each of the pair valve plates, which close the plates quickly and automatically.

-The Quick cloth action preventsthe medium from flowing back.

-Short face to face and good rigidity.

-Easy installation, it can be installed on both horizontal and vertival direction pipelines.

-This valve is tighly sealed, without leakage under the water pressure test.

-Safe and reliable in operation, High interference-resistance.

Applications:

General industrial use.

Dimensions:

| Size | D | D1 | D2 | L | R | t | Weight(kg) | |

| (mm) | (inch) | |||||||

| 40 | 1.5″ | 92 | 65 | 43.3 | 43 | 28.8 | 19 | 1.5 |

| 50 | 2″ | 107 | 65 | 43.3 | 43 | 28.8 | 19 | 1.5 |

| 65 | 2.5″ | 127 | 80 | 60.2 | 46 | 36.1 | 20 | 2.4 |

| 80 | 3″ | 142 | 94 | 66.4 | 64 | 43.4 | 28 | 3.6 |

| 100 | 4″ | 162 | 117 | 90.8 | 64 | 52.8 | 27 | 5.7 |

| 125 | 5″ | 192 | 145 | 116.9 | 70 | 65.7 | 30 | 7.3 |

| 150 | 6″ | 218 | 170 | 144.6 | 76 | 78.6 | 31 | 9 |

| 200 | 8″ | 273 | 224 | 198.2 | 89 | 104.4 | 33 | 17 |

| 250 | 10″ | 328 | 265 | 233.7 | 114 | 127 | 50 | 26 |

| 300 | 12″ | 378 | 310 | 283.9 | 114 | 148.3 | 43 | 42 |

| 350 | 14″ | 438 | 360 | 332.9 | 127 | 172.4 | 45 | 55 |

| 400 | 16″ | 489 | 410 | 381 | 140 | 197.4 | 52 | 75 |

| 450 | 18″ | 539 | 450 | 419.9 | 152 | 217.8 | 58 | 101 |

| 500 | 20″ | 594 | 505 | 467.8 | 152 | 241 | 58 | 111 |

| 600 | 24″ | 690 | 624 | 572.6 | 178 | 295.4 | 73 | 172 |

| 700 | 28″ | 800 | 720 | 680 | 229 | 354 | 98 | 219 |

Product detail pictures:

Related Product Guide:

Manufactur standard Vertical Check Valve - EH Series Dual plate wafer check valve – TWS Valve , The product will supply to all over the world, such as: , , ,