The correct installation of a butterfly valve is crucial for its sealing performance and service life. This document details the installation procedures, key considerations, and highlights the differences between the two common types: wafer-style and flanged butterfly valves. Wafer-style valves, which are installed between two pipeline flanges using stud bolts, have a relatively more complex installation process. In contrast, flanged butterfly valves come with integral flanges and are directly bolted to the mating pipeline flanges, simplifying the process.

The flange bolts for a wafer butterfly valve are relatively long. Their length is calculated as: 2x flange thickness + valve thickness + 2x nut thickness. This is because the wafer butterfly valve itself has no flanges. If these bolts and nuts are removed, the pipelines on both sides of the valve will be disrupted and cannot operate normally.

Flanged valves use shorter bolts, with a length defined as 2x flange thickness + 2x nut thickness, to connect the valve’s own flanges directly to those on the pipeline. A significant advantage of this design is that it allows for one side to be disconnected without interrupting the operation of the opposite pipeline.

This article will mainly introduce the installation instructions for wafer butterfly valves by TWS.

The wafer butterfly valve features a simple, compact, and lightweight design with very few parts. It operates with a quick 90° rotation, enabling simple on/off control and providing excellent flow regulation.

I. Instructions Prior to Installing the Wafer-Type Butterfly Valve

- Before installation begins, the pipeline should be purged of any foreign matter using compressed air and subsequently cleaned with clean water.

- Carefully check whether the usage of the valve conforms to its performance specifications (temperature, pressure).

- Check the valve passage and sealing surface for debris, and remove it promptly.

- After unpacking, the valve should be installed promptly. Do not loosen any fastening screws or nuts on the valve arbitrarily.

- A dedicated butterfly valve flange must be used for wafer type butterfly valves.

- The electric butterfly valve can be installed on pipes at any angle, but for easier maintenance, it is recommended not to install it upside down.

- When installing the butterfly valve flange, it is essential to ensure that the flange face and sealing rubber are aligned, the bolts are tightened evenly, and the sealing surface must fit completely. If the bolts are not tightened uniformly, it may cause the rubber to bulge and jam the disc, or push against the disc, resulting in leakage at the valve stem.

II. Installation: Wafer Butterfly Valve

To ensure a leak-free seal and safe, reliable operation of the butterfly valve, follow the installation procedure below.

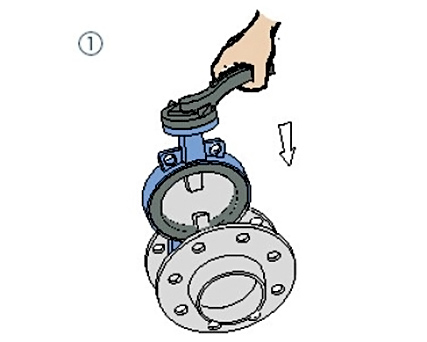

1. As shown, place the valve between the two pre-installed flanges, ensuring that the bolt holes are properly aligned.

2. Gently insert the four pairs of bolts and nuts into the flange holes, and slightly tighten the nuts to correct the flatness of the flange surface;

3. Use spot welding to secure the flange to the pipeline.

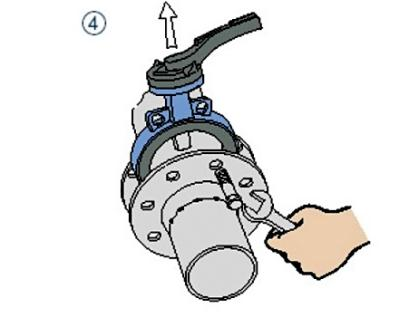

4. Remove the valve;

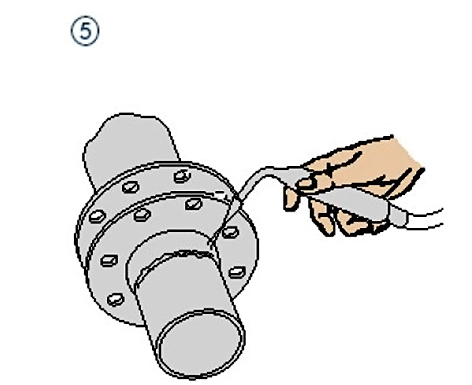

5. Fully weld the flange to the pipeline.

6. Install the valve only after the welded joint has cooled. Ensure that the valve has sufficient room to move within the flange to prevent damage and that the valve disc can open to a certain degree.

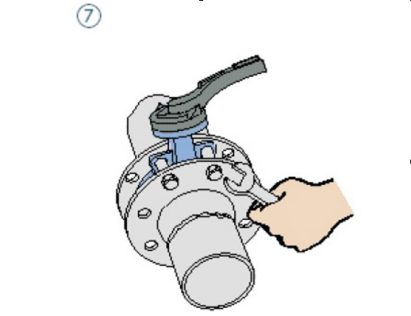

7. Adjust the valve position and tighten the four pairs of bolts (be careful not to overtighten).

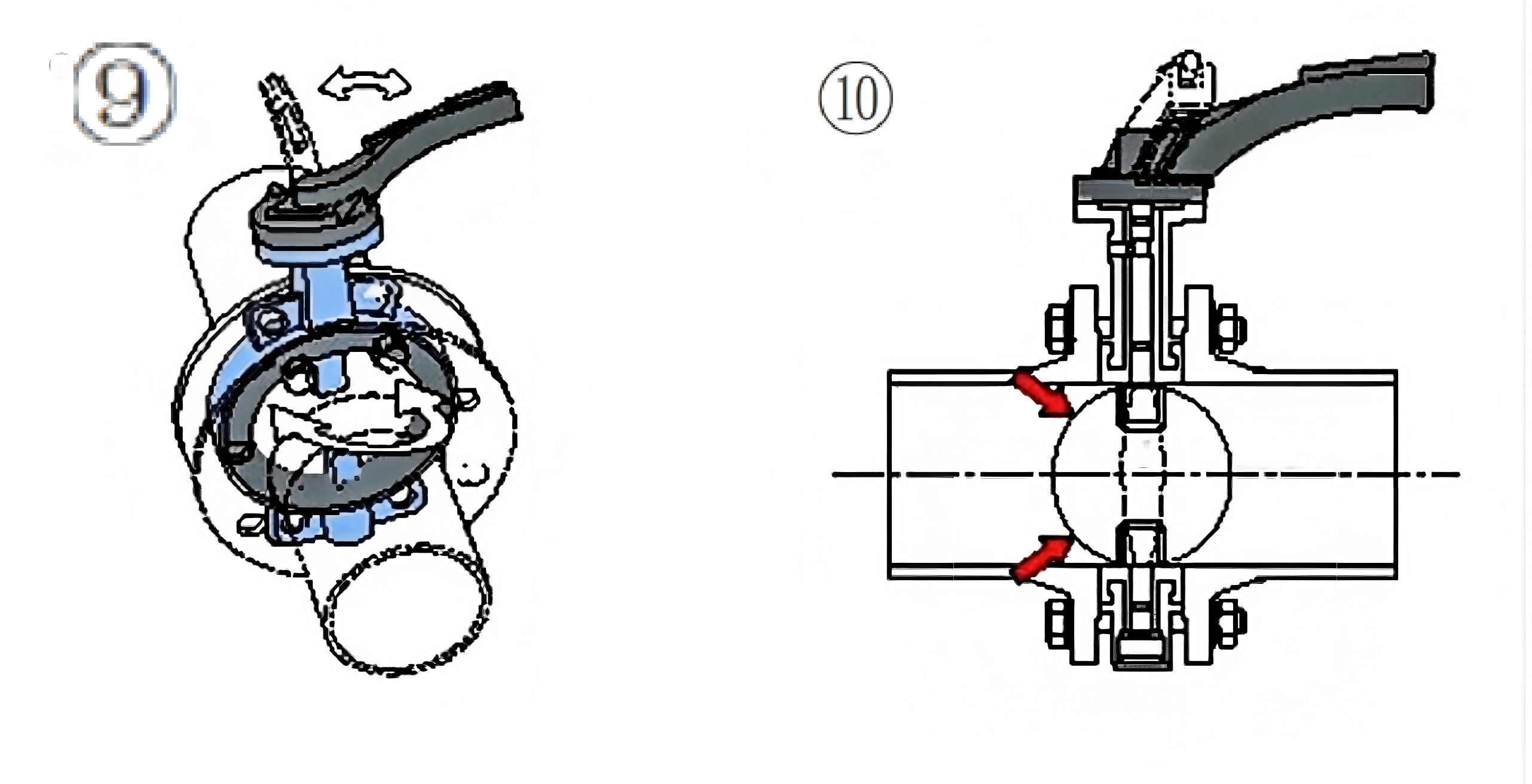

8. Open the valve to ensure that the disc can move freely, then slightly open the disc.

9. Use a cross pattern to tighten all the nuts.

10. Confirm once again that the valve can open and close freely. Note: Make sure the valve disc does not touch the pipeline.

For safe, leak-free operation of wafer butterfly valves, adhere to these principles:

- Handle with Care: Store the valve securely and avoid impacts.

- Align Precisely: Ensure perfect flange alignment to prevent leaks.

- Do Not Disassemble: Once installed, the valve must not be dismantled in the field.

- Install Permanent Supports: Secure the valve with supports that must remain in place.

TWS provides high-quality butterfly valves and comprehensive solutions for gate valve, check valve, and air release valves. Contact us for all your valve needs.

Post time: Nov-08-2025