1. Basic Definition and Structure

A soft sealing flanged concentric butterfly valve (also known as a "center-line butterfly valve") is a quarter-turn rotary valve designed for on/off or throttling flow control in pipelines. Its core features include:

Concentric Design: The valve stem, disc, and seat are aligned on the same central axis, creating a simple and compact structure.

Soft Sealing Mechanism: A flexible elastomeric seal (e.g., rubber, EPDM, NBR) is integrated into the valve body or seat, providing a tight seal to prevent leakage.

Flanged Ends: The valve is equipped with flanged connections, allowing easy installation on pipelines compliant with standards like ANSI, DIN, or JIS.

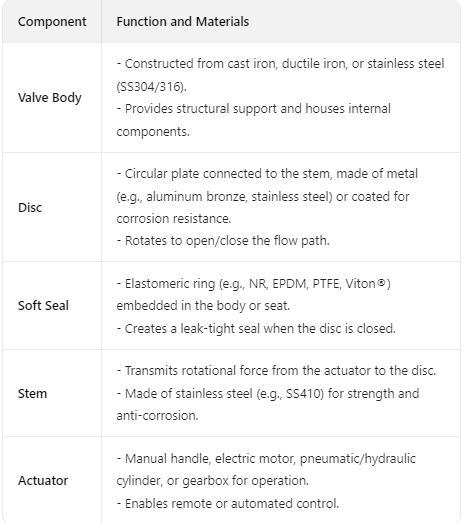

2.Key Components

3. Working Principle

Open Position: The disc rotates 90° to align with the flow direction, minimizing pressure drop and allowing full flow.

Closed Position: The disc rotates back to press against the soft seal, creating a tight shut-off. The concentric design relies on the elastic deformation of the seal to achieve sealing, making it highly effective for low-pressure applications.

4. Key Features and Advantages

Tight Sealing: Soft seals provide excellent leak resistance, often meeting bubble-tight standards (e.g., ANSI B16.104 Class VI, ISO 15848-1).

Low Torque Operation: The concentric design and flexible seal reduce friction, allowing easy manual operation or use with lightweight actuators.

Compact and Lightweight: Compared to gate or globe valves, concentric butterfly valves are smaller and easier to install in limited spaces.

Cost-Effective: Simple structure and low material usage make them affordable for basic flow control needs.

Versatile Media Compatibility: Suitable for water, air, oil, non-corrosive liquids, and granular media (with abrasion-resistant coatings).

5. Technical Specifications

Pressure Rating: Typically low to medium pressure (e.g., PN6–PN16 / Class 125–Class 150).

Temperature Range:

Standard elastomers (e.g., NR, EPDM): -10°C to 90°C (14°F to 194°F).

High-temperature seals (e.g., Viton®, PTFE): -20°C to 150°C (-4°F to 302°F).

Standards Compliance:

Design: EN593, API 609, MSS SP-67.

Flange: ANSI B16.5, ANSI B16.10 DIN EN 1092-1,

Testing: API 598, (leakage tests).

6. Applications

Soft sealing flanged concentric butterfly valves D341X-16Q are widely used in:

Water Supply and Drainage: Municipal water systems, sewage treatment plants, and irrigation networks.

HVAC Systems: Control of air, water, or steam in heating, ventilation, and air conditioning.

Food and Beverage Industry: Sanitary applications with FDA-compliant seals (e.g., EPDM with food-grade coatings).

General Industrial Processes: Non-corrosive fluid handling in chemical, paper, and pharmaceutical plants (for mild media only).

Marine and Shipbuilding: On/off control in seawater or ballast systems (with corrosion-resistant materials).

7. Limitations and Considerations

Pressure and Temperature Limits: Not suitable for high-pressure (e.g., >PN16) or extreme temperature applications (e.g., steam above 150°C).

Corrosion Risks: Metal components (e.g., cast iron bodies) may corrode in aggressive environments; upgrade to stainless steel or coated materials for harsh conditions.

Abrasive Media: Soft seals can wear quickly with particulate-laden fluids; consider hard-seal butterfly valves or additional protective coatings.

Actuator Selection: For large-diameter valves or frequent operation, use pneumatic/hydraulic actuators to avoid manual fatigue.

8. Installation and Maintenance

Installation:

Ensure flanges are aligned and bolts are tightened uniformly to prevent leakage.

Avoid installing the valve under excessive pipeline stress.

Maintenance:

Regularly inspect the seal for wear or cracking, especially in high-cycle applications.

Lubricate the stem and actuator periodically to ensure smooth operation.

Replace the seal if leakage occurs; some designs allow seal replacement without removing the valve from the pipeline.

9. Supplier and Product Selection Tips

Material Certification: Ensure seals meet industry standards (e.g., FDA for food, ATEX for explosive environments).

Customization Options: Some suppliers offer anti-static designs, fire-safe features, or special coatings (e.g., epoxy, PTFE) for niche applications.

Conclusion

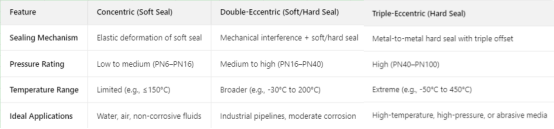

Soft sealing flanged concentric butterfly valves are a cost-effective, reliable solution for low-to-medium pressure flow control in non-critical applications. Their simplicity, tight sealing, and ease of maintenance make them a popular choice in water, HVAC, and general industrial systems. For more demanding environments, upgrading to eccentric designs or premium materials is recommended. Always evaluate media properties, operating conditions, and compliance requirements to select the optimal valve for your needs.

Any rubber seated concentric butterfly valve, such as wafer butterfly valve, lug butterfly valve D7L1X-16Q, Y-strainer, wafer check valve, gate valve Z41X-16Q demands, can contact with TWS valve factory, we will reply you at the first time.

Post time: Jun-07-2025