- Material Selection

Low-End Valves

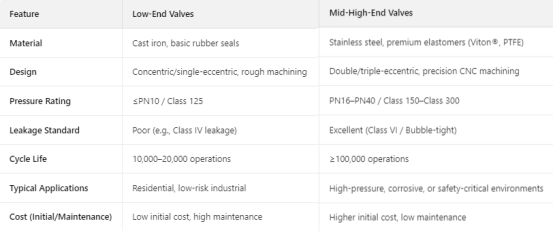

- Body/Disc Materials: Typically use low-cost metals like cast iron or unalloyed carbon steel, which may lack corrosion resistance in harsh environments.

- Sealing Rings: Made of basic elastomers such as NR (natural rubber) or low-grade EPDM, with limited chemical resistance and temperature tolerance (e.g., ≤80°C / 176°F).

- Shaft: Often constructed from ordinary carbon steel without surface treatment, prone to rust in wet or acidic conditions.

Mid-High-End Valves

- Body/Disc Materials: Utilize premium materials like stainless steel (SS304/316), ductile iron, or aluminum bronze for superior corrosion resistance and mechanical strength.

- Sealing Rings: Employ high-performance elastomers such as FDA-compliant EPDM, NBR, PTFE, or Viton®,offering broader chemical compatibility (e.g., resistant to oils, acids, or solvents) and higher temperature ranges (-20°C to 150°C / -4°F to 302°F).

- Shaft: Made of stainless steel (SS410/316) with polished or coated surfaces (e.g., nickel plating) to prevent wear and leakage.

- Structural Design & Manufacturing

Low-End Valves

- Simplified Design: Basic concentric or single-eccentric structures with limited sealing precision. The disc and seat may have rough machining, leading to higher friction and torque.

- Assembly: Often mass-produced with minimal quality control, resulting in inconsistent tolerances. Leakage rates may fail to meet strict standards (e.g., exceed ANSI B16.104 Class VI requirements).

- Actuation: Typically paired with low-cost manual handles or basic electric actuators, lacking durability for frequent operation.

Mid-High-End Valves

- Advanced Design: Feature double-eccentric or triple-eccentric structures to reduce friction, enhance sealing efficiency, and minimize wear. For example, double-eccentric designs create a "wedging effect" for tighter shut-off.

- Precision Manufacturing: Machined with high-precision CNC equipment, ensuring smooth disc movement and optimal seal contact. Leakage rates often meet or exceed ISO 15848-1 (e.g., Bubble-tight Class A).

- Actuation: Compatible with premium actuators (pneumatic, hydraulic, or intelligent electric actuators) for high-speed, high-cycle applications. Some models include positioners or feedback sensors for automation.

3. Performance & Reliability

Low-End Valves

- Pressure/Temperature Limits: Suitable for low-pressure systems (e.g., ≤PN10 / Class 125) and narrow temperature ranges. May fail in high-pressure (e.g., >PN16) or extreme temperature (-10°C to 90°C) environments.

- Service Life: Shortened due to poor material durability and design flaws, requiring frequent maintenance or replacement (e.g., 10,000–20,000 cycles).

- Leakage Risk: Higher chance of seal deformation or shaft corrosion, leading to environmental leaks or system failures.

Mid-High-End Valves

- Pressure/Temperature Limits: Designed for medium-to-high pressure systems (e.g., PN16–PN40 / Class 150–Class 300) and broader temperature ranges (-30°C to 200°C / -22°F to 392°F).

- Service Life: Engineered for long-term reliability, with cycle life exceeding 100,000 operations. Some premium models offer lifetime warranties.

- Leakage Control: Advanced seals and anti-blowout shafts reduce leakage risks, making them suitable for critical applications like gas systems or hazardous fluid handling.

4. Applications

Low-End Valves

- Suitable For: Non-critical, low-risk applications with basic flow control needs, such as:

- Residential water supply systems

- Simple HVAC ductwork

- Low-pressure irrigation or drainage

- Avoid Use In: High-pressure industrial pipelines, corrosive media, or safety-critical environments (e.g., oil & gas, pharmaceuticals).

Mid-High-End Valves

- Ideal For: Demanding industrial and commercial applications, including:

- Chemical processing plants (corrosive fluids)

- Food & beverage production (sanitary standards)

- Power generation (high-temperature steam)

- Oil & gas (explosion-proof requirements)

- Key Standards: Often certified to ISO, API, ASME, or ATEX for compliance with international safety and quality regulations.

5. Cost & Maintenance

Low-End Valves

- Initial Cost: Significantly cheaper (20–50% less than mid-high-end models), making them appealing for budget-sensitive projects.

- Maintenance: Higher long-term costs due to frequent seal replacements, shaft lubrication, or corrosion repairs.

- Downtime Risk: More prone to unexpected failures, leading to production losses in industrial settings.

Choosing the Right Valve (eg. TWS Valve)

- Low-End: Suitable for short-term, non-critical uses where cost is the primary concern.

- Mid-High-End: Invest in these for reliability, safety, and long-term performance in challenging applications. Always consider media type, operating conditions, and compliance requirements when selecting a valve.

This differentiation highlights why mid-high-end valves D371X-16Q are preferred in industries prioritizing safety and efficiency, while low-end options serve basic, cost-driven needs.

Soft Seal, Hard Performance wafer butterfly valve, Double flange butterfly valve D34B1X-10Q, Gate valve, Y-strainer, Wafer dual plate check valve,-Engineered for Leak Fredd solutions. Tight Seal, Unmatched Reliability, Your flow Control Expert.

Post time: Jun-07-2025