Butterfly valves play a crucial role in controlling the flow of various liquids and gases. Among different types of butterfly valves, lug butterfly valves and wafer butterfly valves are two widely used choices. Both types of valves have unique functions and are suitable for specific applications. TWS will explore their similarities and differences in this article, hoping to help you make informed decisions when choosing the appropriate valve.

I. The similarities between them.

1. Working Principle.

Both wafer type butterfly valves and lug type butterfly valves control the flow rate of the medium by rotating the valve disc. The rotation angle of the valve disc can only be between 0 to 90 degrees, that means, the valve is fully open at 90 degrees and fully closed at 0 degrees. This is the working principle of butterfly valves.

2. Same Face to Face

The wafer butterfly valve and the lug butterfly valve are designed as thin type, which occupy less space and are suitable for installation in the pipeline system with limited space.

3. Standardized design:

Both comply with international industrial standards, are easy to connect with standard flanges, and can be easily replaced in existing systems.

| Project | Standard |

| Process Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Sealing Test | ISO5208 | API598 | EN12266-1 |

II. What’s the difference?

Both wafer type butterfly valves and lug type butterfly valves refer to the connection form of butterfly valves, with the same structural length and similar purposes, but there are significant differences in design, installation, application, cost, and other aspects.

1. Design Differences

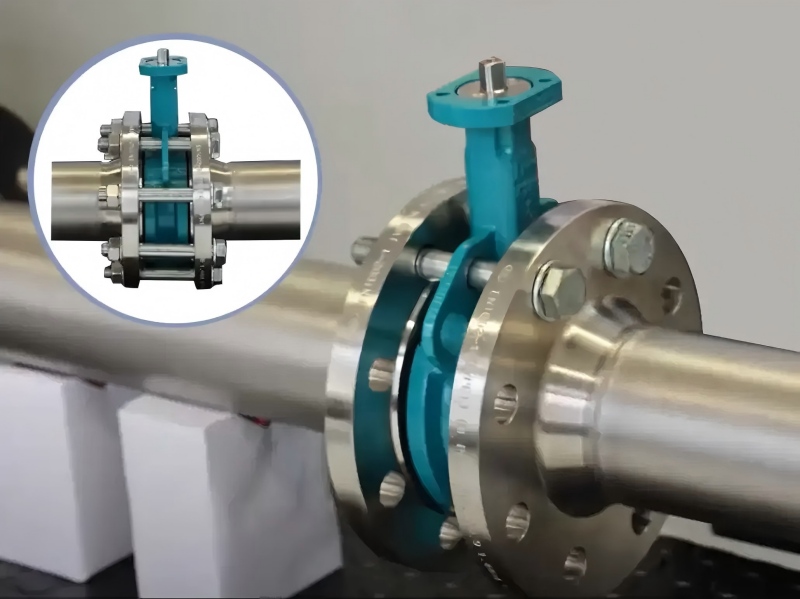

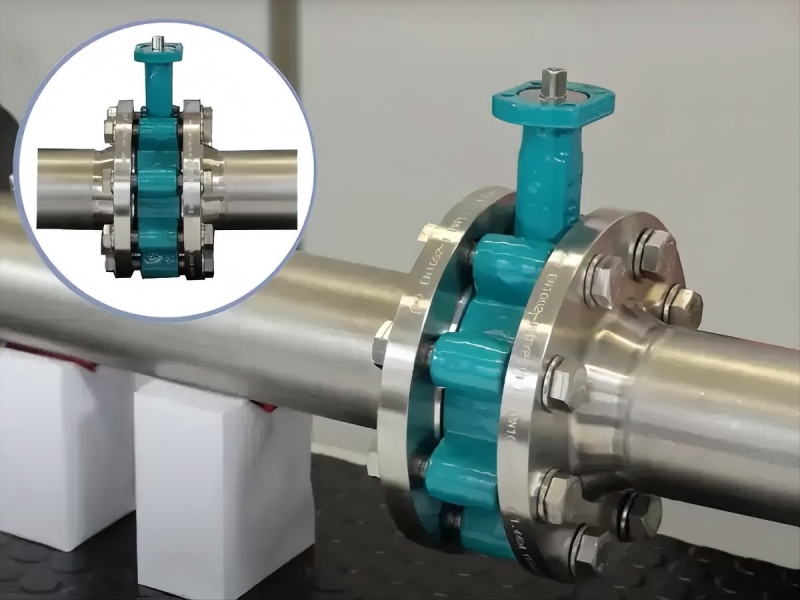

Lug butterfly valve: Both ends of the valve body are designed with threaded lugs, which are more conducive to fixing the valve.

Wafer butterfly valve: On the contrary, it does not have any threaded inserts, but is clamped between two flanges, with bolts passing through the pipeline flange and valve body to fix it. That is to say, it is designed by the pressure of the bolts squeezing the pipeline flange.

2. Installation Process.

Lug butterfly valves are suitable for pipelines that require regular maintenance or frequent disassembly. Threaded inserts are easy to install and disassemble without damaging the entire pipeline system. The protruding butterfly valve can be installed at the end of the pipeline and used as a terminal valve.

- Ensure that the lugs are aligned correctly with the flange bolts to avoid pressure on the valve body.

- Use appropriate gasket materials when necessary to prevent leakage, especially in medium pressure systems.

- Tighten the bolts evenly to maintain uniform pressure inside the valve.

Wafer butterfly valves are more suitable for connecting both ends of pipelines in situations where space is limited, but they cannot be used as terminal valves as they may detach.

- Verify flange compatibility (e.g. ANSI, DIN) to ensure sealing.

- Avoid excessive tightening of flange bolts to prevent deformation of the machine body.

- Installed in the system with minimal pipeline vibration to prevent loosening.

3. Sealing Mechanism.

The lug butterfly valve provides a tighter seal due to threaded connections and safety bolts, ensuring leak free operation and preventing fluid backflow.

On the contrary, the wafer type butterfly valve relies on compression between two flanges to achieve reliable sealing, so it needs to be installed completely aligned with the pipeline to avoid misalignment and leakage.

4. DN & PN

- Wafer on butterfly valves are usually smaller than DN600, and single flange butterfly valves can be used for larger diameters. They are generally suitable for situations where the pressure is ≤ PN16.

-The lug butterfly valve has a larger diameter and can handle higher pressure levels, up to PN25, because the installation of the lug butterfly valve is more secure.

5. Cost

Lug butterfly valves and wafer butterfly valves differ in cost-effectiveness.

Wafer butterfly valves are usually more economical because they have simpler designs, simpler processing, and require less material.

The lug butterfly valve requires threading, so the machining process is relatively complex.

III. Conclusion

Both lug butterfly valves and wafer butterfly valves are used to control fluid flow, but there are significant differences in design, installation, sealing, diameter, pressure rating, and cost between this two. When choosing, it can be determined according to specific needs: if frequent disassembly and maintenance are required, it is advisable to choose a protruding ear type; If space is tight and cost is a concern, the wafer on design is more suitable. Understanding these differences can help you choose more compatible valves and achieve efficient and reliable flow control. TWS is not only a reliable partner for high-quality butterfly valves, but also has deep technical accumulation and mature solutions in the fields of gate valves, check valves, air release valve, etc. No matter what fluid control needs you, we can provide you with professional and complete one-stop valve support. If you have any intention of cooperation or technical consultation, please feel free to communicate with us at any time.

Post time: Dec-11-2025