Product Definition

The Soft Sealing Flange Double Eccentric Butterfly Valve (Dry Shaft Type) is a high-performance valve designed for precise flow control in pipelines. It features a double-eccentric structure and a soft sealing mechanism, combined with a “dry shaft” design where the shaft is isolated from the medium flow. This configuration ensures reliable sealing, low torque operation, and resistance to corrosion and abrasion, making it ideal for applications requiring tight shut-off and minimal maintenance.

Key Structural Features

-

- First Eccentricity: The valve shaft is offset from the center of the disc, reducing friction during opening/closing and minimizing wear on the sealing surfaces.

- Second Eccentricity: The shaft is further offset from the pipeline centerline, creating a “wedging effect” that enhances sealing performance as the disc closes.

- Benefit: Provides superior sealing reliability and extends service life compared to single-eccentric or concentric designs.

-

Soft Sealing Mechanism

- The valve uses a soft sealing ring (typically made of EPDM, NBR, or PTFE) embedded in the valve body or disc, ensuring airtight closure and compatibility with various media (e.g., water, oils, gases, and non-abrasive fluids).

- Advantage: Low leakage rates (meeting API 598 or ISO 15848 standards) and minimal torque required for operation.

-

Dry Shaft Construction

- The shaft is sealed separately from the media flow, preventing direct contact with the fluid. This design eliminates potential leakage paths through the shaft and reduces corrosion risks, especially in aggressive environments.

- Key Component: High-quality stem seals (e.g., V-type packing or mechanical seals) ensure zero leakage along the shaft.

-

Flange Connection

- Designed with standard flange interfaces (e.g., ANSI, DIN, JIS) for easy installation in pipelines. The flanged design provides structural stability and simplifies maintenance.

Working Principle

- Opening: As the shaft rotates, the double-eccentric disc moves from the closed position, gradually disengaging from the soft seal. The eccentric offsets reduce initial contact stress, enabling smooth, low-torque operation.

- Closing: The disc rotates back, and the double-eccentric geometry creates a progressive sealing action. The wedging effect increases contact pressure between the disc and seal, ensuring a tight shut-off.

- Note: The dry shaft design ensures that the shaft remains unaffected by media temperature, pressure, or corrosiveness, enhancing overall reliability.

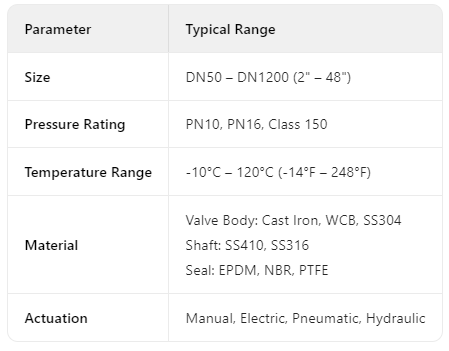

Technical Specifications

- Water Treatment: Drinking water, wastewater, and sewage systems (requires high sealing for hygienic standards).

- Chemical Industry: Corrosive fluids, acids, and alkalis (dry shaft protects against chemical attack).

- HVAC Systems: Air conditioning and heating pipelines (low torque for frequent operation).

- Petrochemical & Oil/Gas: Non-abrasive media like oil, gas, and solvents (reliable shut-off in critical processes).

- Food & Beverage: Sanitary applications (FDA-compliant seals ensure product safety).

-

Advantages Over Traditional Valves

- Superior Sealing: Soft seals eliminate leakage, suitable for applications requiring environmental protection or high purity.

- Energy Efficiency: Low torque operation reduces actuation power requirements, lowering operational costs.

- Longevity: Double-eccentric design minimizes wear, while the dry shaft protects against corrosion, extending service life.

- Space-Saving: Compact structure compared to gate or globe valves, ideal for limited-space installations.

Maintenance & Installation Tips

- Installation: Ensure flanges are aligned and bolts are evenly tightened to avoid stress on the valve body.

- Maintenance: Regularly inspect the soft seal for wear and replace if damaged. Lubricate the shaft and actuator periodically to ensure smooth operation.

- Storage: Store in a dry, dust-free environment with the valve slightly open to relieve stress on the seal.

This valve combines advanced engineering with practical design, offering a reliable and cost-effective solution for modern industrial flow control needs. For specific customization (e.g., material upgrades or special coatings), please consult the manufacturer.

Post time: May-23-2025