OEM/ODM Factory Abo Butterfly Valve - GD Series grooved end butterfly valve – TWS Valve

OEM/ODM Factory Abo Butterfly Valve - GD Series grooved end butterfly valve – TWS Valve Detail:

Description:

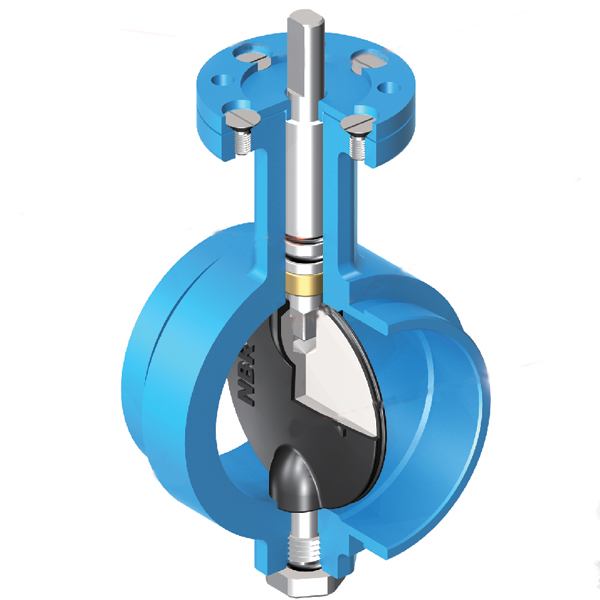

GD Series grooved end butterfly valve is a grooved end bubble tight shutoff butterfly valve with outstanding flow characteristics. The rubber seal is molded onto the ductile iron disc, in order to allow for maximum flow potential. It offers economical, efficient, and reliable service for grooved end piping applications. It is easily installed with two grooved end couplings.

Typical application:

HVAC, filtering system, etc.

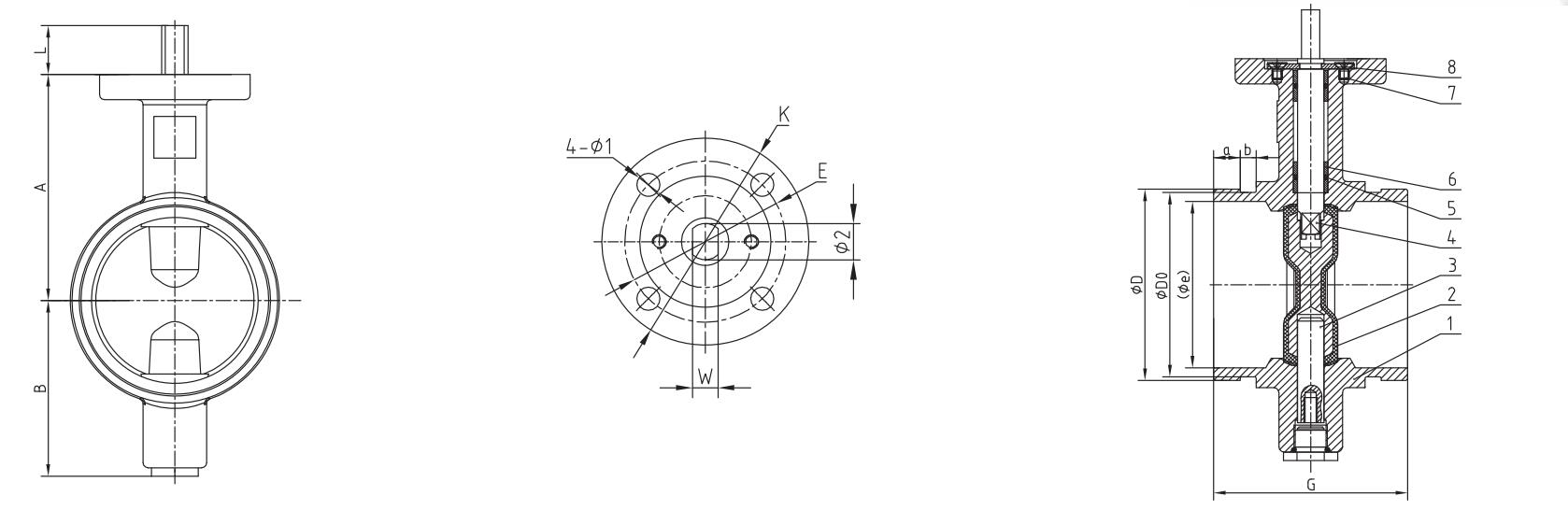

Dimensions:

| Size | A | B | D | D1 | D2 | L | H | E | F | G | G1 | I | P | W | U | K | Φ1 | Φ2 | Weight (kg) | |

| mm | inch | |||||||||||||||||||

| 50 | 2 | 98.3 | 61 | 51.1 | 78 | 35 | 32 | 9.53 | 50 | 57.15 | 60.33 | 81.5 | 15.88 | 50.8 | 9.52 | 49.5 | 77 | 7 | 12.7 | 2.6 |

| 65 | 2.5 | 111.3 | 65 | 63.2 | 92 | 35 | 32 | 9.53 | 50 | 69.09 | 73.03 | 97.8 | 15.88 | 63.5 | 9.52 | 61.7 | 77 | 7 | 12.7 | 3.1 |

| 80 | 3 | 117.4 | 75 | 76 | 105 | 35 | 32 | 9.53 | 50 | 84.94 | 88.9 | 97.8 | 15.88 | 76.2 | 9.52 | 74.5 | 77 | 7 | 12.7 | 3.5 |

| 100 | 4 | 136.7 | 90 | 99.5 | 132 | 55 | 32 | 9.53 | 70 | 110.08 | 114.3 | 115.8 | 15.88 | 101.6 | 11.1 | 98 | 92 | 10 | 15.88 | 5.4 |

| 150 | 6 | 161.8 | 130 | 150.3 | 185 | 55 | 45 | 9.53 | 70 | 163.96 | 168.3 | 148.8 | 15.88 | 152.4 | 17.53 | 148.8 | 92 | 10 | 25.4 | 10.5 |

| 200 | 8 | 196.9 | 165 | 200.6 | 239 | 70 | 45 | 11.1 | 102 | 214.4 | 219.1 | 133.6 | 19.05 | 203.2 | 20.02 | 198.8 | 125 | 12 | 28.58 | 16.7 |

| 250 | 10 | 228.6 | 215 | 250.7 | 295 | 70 | 45 | 12.7 | 102 | 368.28 | 273.1 | 159.8 | 19.05 | 254 | 24 | 248.8 | 125 | 12 | 34.93 | 27.4 |

| 300 | 12 | 266.7 | 258 | 301 | 350 | 70 | 45 | 12.7 | 102 | 318.29 | 323.9 | 165.1 | 19.05 | 304.8 | 26.92 | 299.1 | 125 | 12 | 38.1 | 37.2 |

Product detail pictures:

Related Product Guide:

OEM/ODM Factory Abo Butterfly Valve - GD Series grooved end butterfly valve – TWS Valve , The product will supply to all over the world, such as: , , ,

Write your message here and send it to us