1 Treatment method for increasing pneumatic valve leakage

If the case of the valve spool is worn to reduce the leakage of the valve, it is necessary to clean and remove the foreign body; if the pressure difference is large, the actuator of the pneumatic valve is improved to increase the gas source and reduce the leakage. In addition, when installing the pneumatic valve, the selected stem length should be moderate to prevent leakage caused by the valve is not completely closed.

2 The method of pneumatic valve

For the instability of the pneumatic valve caused by the unstable signal pressure, the stable operation of the power network system should be ensured; the positioning device should be adjusted, and a new positioner can be replaced when necessary to ensure the stability of the air source pressure. You can also reinstall the valve stem or add lubricant to reduce the friction of the contact part of the valve stem, reduce the instability of the pneumatic valve, but also can adjust the precision of the position of the positioning device pipe, so as to eliminate the unstable fault of the pneumatic valve.

3 pneumatic valve vibration fault treatment method

For the vibration of the pneumatic valve caused by the friction between the bushing and the valve core, the bushing needs to be replaced immediately; for the vibration of the pneumatic valve around the pneumatic valve, eliminate the vibration and replace the vibration of the pneumatic valve base; analyze and judge the vibration caused by the current flow direction of the single seat valve, and adjust the correct installation direction of the pneumatic valve.

4 Pneumatic valve action slow fault handling method

The slow action of pneumatic valve is mainly related to the damage of the diaphragm, so the new diaphragm should be replaced in time; carefully check whether the graphite and asbestos packing lubricating oil and PTFE fill are normal, and replace it if necessary to ensure that they shall remove the foreign body in the valve body in time to ensure the cleanliness of the valve body; handle the valve stem, reduce the friction between the valve stem and the surrounding components, so as to solve the slow failure of pneumatic valve action.

5 pneumatic valve

For the gas source but the pneumatic valve does not act, it is necessary to check the instruction line one by one to eliminate the fault in time. When the position-er in the pneumatic valve has no input and display, it is necessary to replace the new locator in time; for the serious deformation of the valve core and stem, it should be replaced in time to ensure the proper position of the hand wheel.

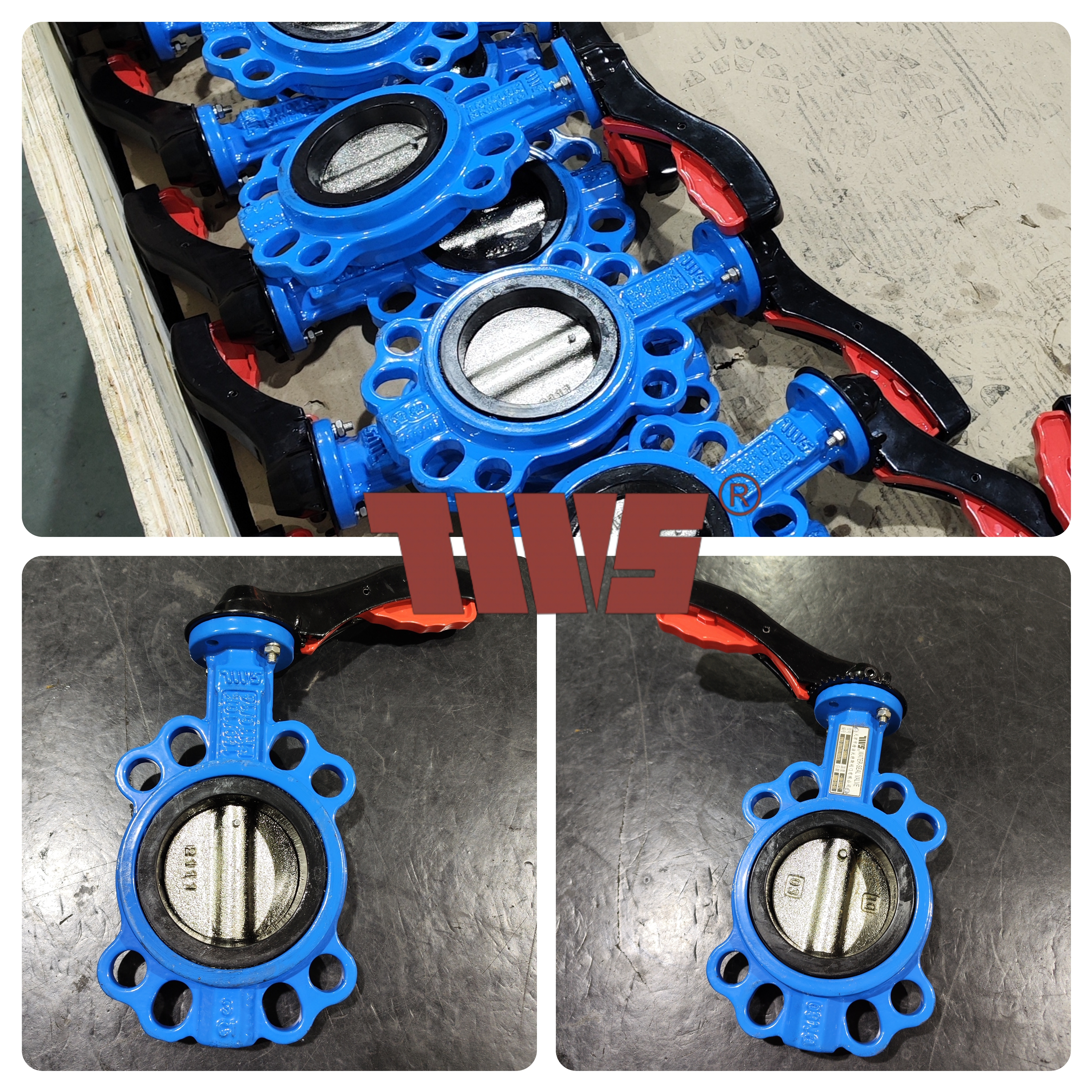

Besides, Tianjin Tanggu Water Seal Valve Co., Ltd. is a technologically advanced elastic seat valve supporting enterprises, the products are rubber seat wafer butterfly valve, lug butterfly valve, double flange concentric butterfly valve, double flange eccentric butterfly valve, balance valve, wafer dual plate check valve, Y-Strainer and so on. At Tianjin Tanggu Water Seal Valve Co., Ltd., we pride ourselves on providing first-class products that meet the highest industry standards. With our wide range of valves and fittings, you can trust us to provide the perfect solution for your water system. Contact us today to learn more about our products and how we can help you.

Post time: May-09-2024