What are some important factors to consider when selecting the correct seal material for an application?

Great price and qualified colors

Availability of seals

All influencing factors in the sealing system: e.g. temperature range, fluid and pressure

These are all important factors to consider in your sealing system. If all the factors are known, it will be easy to choose the right material.

But the prerequisite is that the material must be durable. So the first thing to consider is technical performance. Let’s start with the performance factor.

System lifetime and cost are important factors (TIanjin Tanggu Water-Seal Valve Co.,ltd) to consider. All factors will affect your application performance. It is important to consider design factors according to the application. This includes materials used, hardware shapes and production processes. There are also environmental factors to consider including: pressure, temperature, time, assembly and media.

elastomer

Elastomers are popular for their good elasticity. No other material has the same level of elasticity.

Other materials such as polyurethanes and thermoplastics are much more resistant to pressure than elastomers.

Rubber materials can be used in a variety of different applications.

Important mechanical properties include

elasticity

hardness

tensile strength

Other important features include

• Compression set

• heat resistance

• low temperature flexibility

• chemical compatibility

• Anti-aging

• abrasion resistance

The most important feature is the elasticity of the rubber material. Let’s learn more about this.

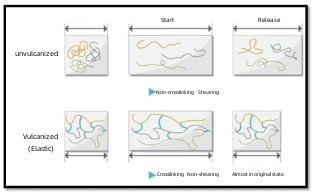

Elasticity is the result of vulcanization. Elastomeric materials, such as vulcanized rubber, will return to their original shape if deformed.

Inelastic materials, such as unvulcanized rubber, will not return to their original state if deformed. Vulcanization (such as double flange butterfly valve) is the process of converting rubber into an elastomeric material.

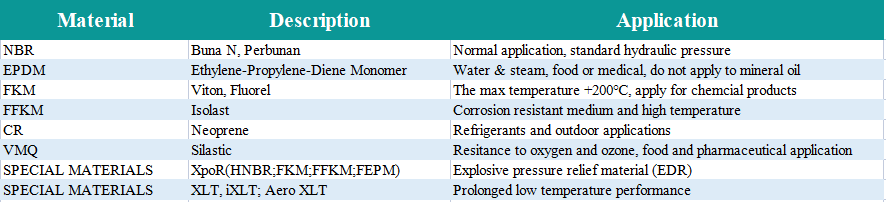

The selection of elastomers is mainly based on:

•range of working temperature

• Resistance to liquids and gases

• Resistance to weathering, ozone and UV rays

The selection of elastomers is mainly based on:

•range of working temperature

• Resistance to liquids and gases

• Resistance to weathering, ozone and UV rays

Six factors that must be considered when selecting valve sealing surface materials

The sealing surface is the most critical working surface of the valve, the quality of the sealing surface directly affects the service life of the valve, and the material of the sealing surface is an important factor to ensure the quality of the sealing surface. Therefore, the following factors should be considered when selecting the valve sealing surface material:

① Corrosion resistance. “Corrosion” is the process in which the surface of the sealing surface is damaged under the action of the medium. If the surface of the sealing surface is corroded, the sealing performance cannot be guaranteed, so the material of the sealing surface must be corrosion-resistant. The corrosion resistance of a material mainly depends on the composition of the material and its chemical stability.

② Anti-abrasion. “Scratch” refers to the damage caused by friction of the material during the relative movement of the sealing surface. This kind of damage will inevitably cause damage to the sealing surface. Therefore, the sealing surface material must have good anti-scratch properties, especially for gate valves. The scratch resistance of a material is often determined by the internal properties of the material.

③Erosion resistance. “Erosion” is the process of destroying the sealing surface when the medium flows through the sealing surface at high speed. This kind of damage is more obvious on throttle valves and safety valves used in high temperature and high pressure steam media, and has a great impact on the damage of sealing performance. Therefore, erosion resistance is also one of the important requirements for sealing surface materials.

④It should have a certain hardness, and the hardness will drop greatly under the specified working temperature.

⑤ The linear expansion coefficient of the sealing surface and the body material should be similar, which is more important for the structure of the sealing ring, so as to avoid extra stress and loosening at high temperature.

⑥Used under high temperature conditions, there must be sufficient anti-oxidation, thermal fatigue resistance and thermal cycle issues.

Under the current circumstances, it is difficult to find a sealing surface material that fully meets the above requirements. We can only focus on meeting the requirements of certain aspects according to different valve types and uses. For example, valves used in high-speed media should pay special attention to the erosion resistance requirements of the sealing surface; and when the medium contains solid impurities, the sealing surface material with higher hardness should be selected.

Post time: Mar-08-2023