There are many kinds of butterfly valves, and there are many classification methods.

1. Classification by structural form

(1) concentric butterfly valve; (2) single-eccentric butterfly valve; (3) double-eccentric butterfly valve; (4) three-eccentric butterfly valve

2. Classification according to the sealing surface material

(1) Resilient butterfly valve

(2) Metal-type hard-sealed butterfly valve. The sealing pair is composed of metal hard material to metal hard material.

3. Classification by sealed form

(1) Forced sealed butterfly valve.

(2) Pressure sealing butterfly valve. The seal pressure is generated by the elastic sealing element on the seat or plate.

(3) Automatic sealed butterfly valve. The seal specific pressure is automatically generated by the medium pressure.

4. Classification by work pressure

(1) The vacuum butterfly valve. Butterfly valve with a working pressure lower than the standard atmosphere.

(2) Low-pressure butterfly valve. Butterfly valve with a nominal pressure of PN≤1.6MPa.

(3) Medium-pressure butterfly valve. The nominal pressure PN is the butterfly valve of 2.5∽6.4MPa.

(4) High-pressure butterfly valve. The nominal pressure PN is the butterfly valve of 10.0∽80.OMPa.

(5) Ultra-high pressure butterfly valve. Butterfly valve with a nominal pressure PN <100MPa.

5. Classification by connection mode

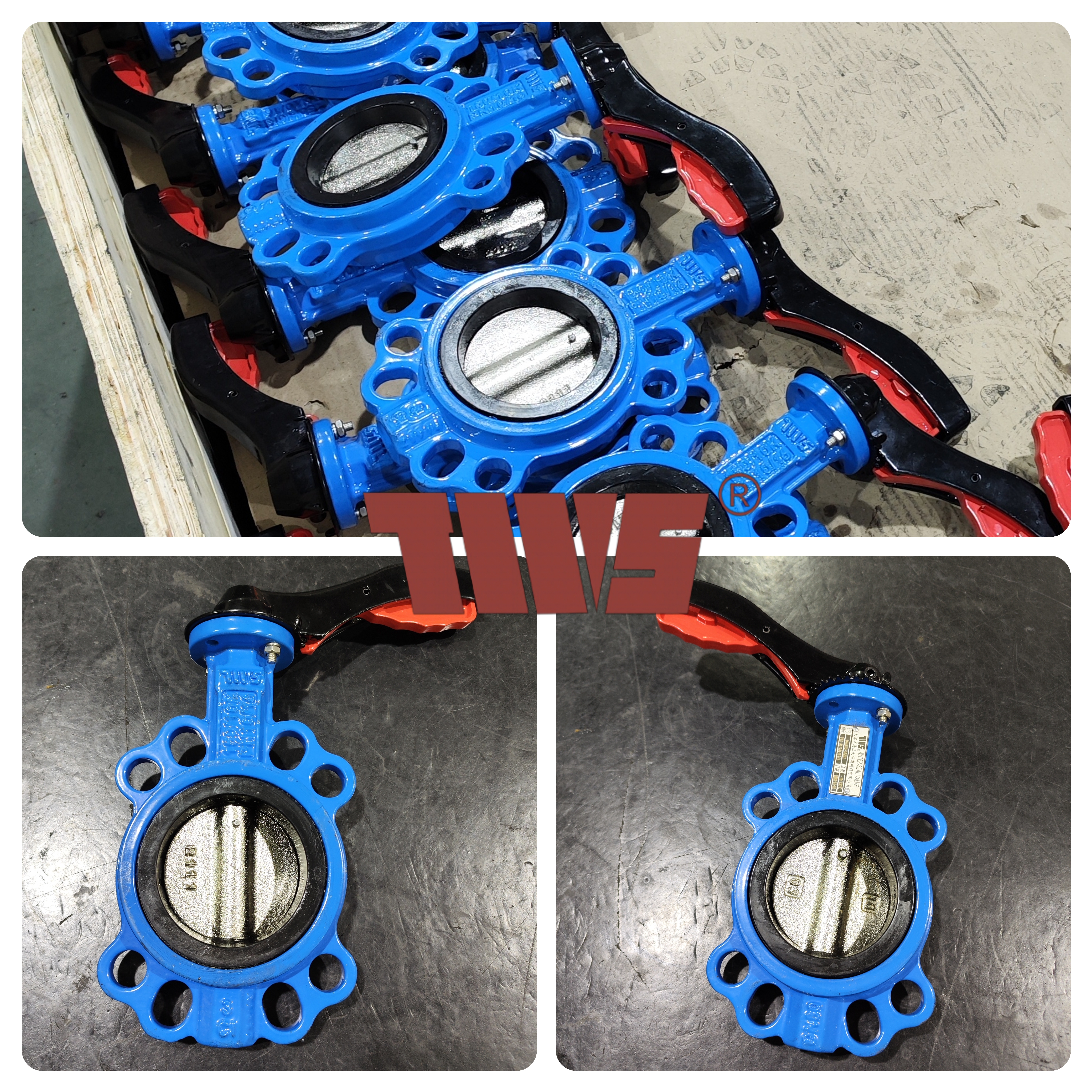

(1) Wafer butterfly valve

(2) Flange butterfly valve

(3) Lug butterfly valve

(4) Welded butterfly valve

Concentric Butterfly valve is a kind of valve which opens and closes with a circular butterfly plate and opens, closes and adjusts the fluid channel with the rotation of the valve stem. The butterfly plate of the butterfly valve is installed in the diameter direction of the pipe. In the cylindrical channel of the butterfly valve body, the disc butterfly plate rotates around the axis, and the rotation Angle is between 0 and 90. When the rotation reaches 90, the valve is fully open.

Key points of construction and installation

1) The installation position, height, import and export direction must meet the design requirements, and the connection should be firm and tight.

2) The handle of all kinds of manual valves installed on the thermal insulation pipe shall not be downward.

3) The valve must be inspected externally before the installation, and the nameplate of the valve shall meet the provisions of the current national standard “General Valve Mark” GB 12220. For valves with working pressure greater than 1.0 MPa and cutting off on the main pipe, strength and tight performance tests shall be conducted before installation and shall be used after qualified. In the strength test, the test pressure is 1.5 times of the nominal pressure, and the duration is not less than 5min. The valve shell and packing should be qualified without leakage. For the tightness test, the test pressure is 1.1 times of the nominal pressure; the test pressure shall meet the GB 50243 standard for the duration of the test, and the valve seal surface is qualified.

Product selection of the key points

1. The main control parameters of the butterfly valve are the specifications and dimensions.

2. The butterfly valve is a single plate wind valve, its simple structure, convenient processing, low cost, simple operation, but the adjustment accuracy is poor, only suitable for ventilation and air conditioning system for switch or coarse adjustment of the occasion.

3. Can be manual, electric or zipper type operation, can be fixed at any Angle of 90 range.

4. Due to the single axial single valve plate, the bearing force is limited, in the condition of large pressure difference, large flow rate when the valve service life is short. The valve has closed type and ordinary type, insulation and non-insulation.

5. The electric butterfly valve only has dual type control, the electric actuator is the same as the multi-leaf valve.

Post time: Oct-26-2023