Products News

-

Difference between soft seal butterfly valve and hard seal butterfly valve

Hard seal butterfly valve Hard sealing of butterfly valve refers to that both sides of the sealing pair are made of metal materials or other hard materials. The sealing performance of this kind of seal is poor, but it has high temperature resistance, wear resistance and good mechanical performanc...Read more -

Applicable occasions for butterfly valve

Butterfly valves are suitable for pipelines that transport various corrosive and non-corrosive fluid media in engineering systems such as coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting, power generation and environmental protection, and are used to a...Read more -

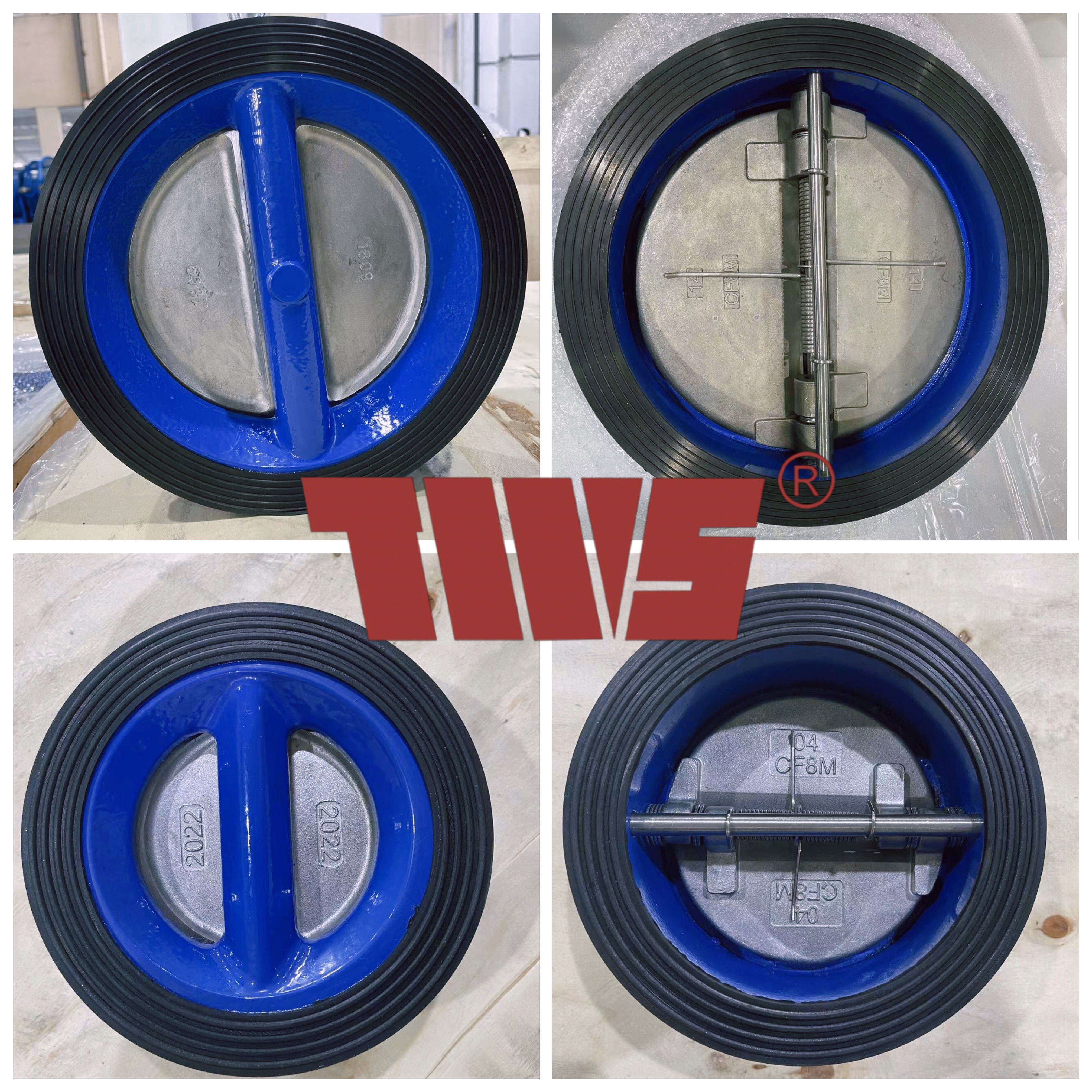

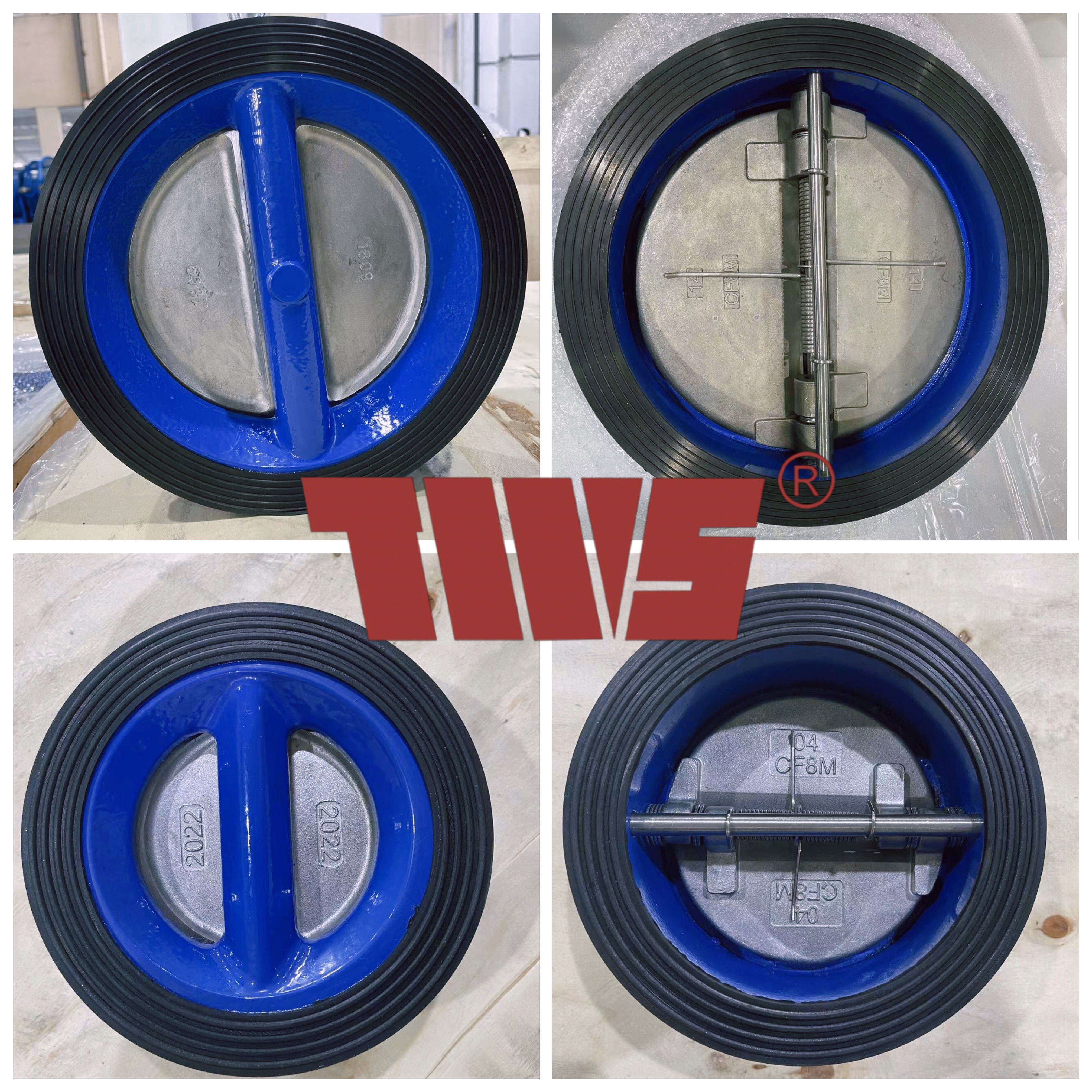

Introduction to the application, main material and structural characteristics of the wafer dual plate check valve

Wafer dual plate check valve refers to the valve that automatically opens and closes the valve flap by relying on the flow of the medium itself to prevent the backflow of the medium, also known as check valve, one-way valve, reverse flow valve and back pressure valve. Wafer dual plate check valve...Read more -

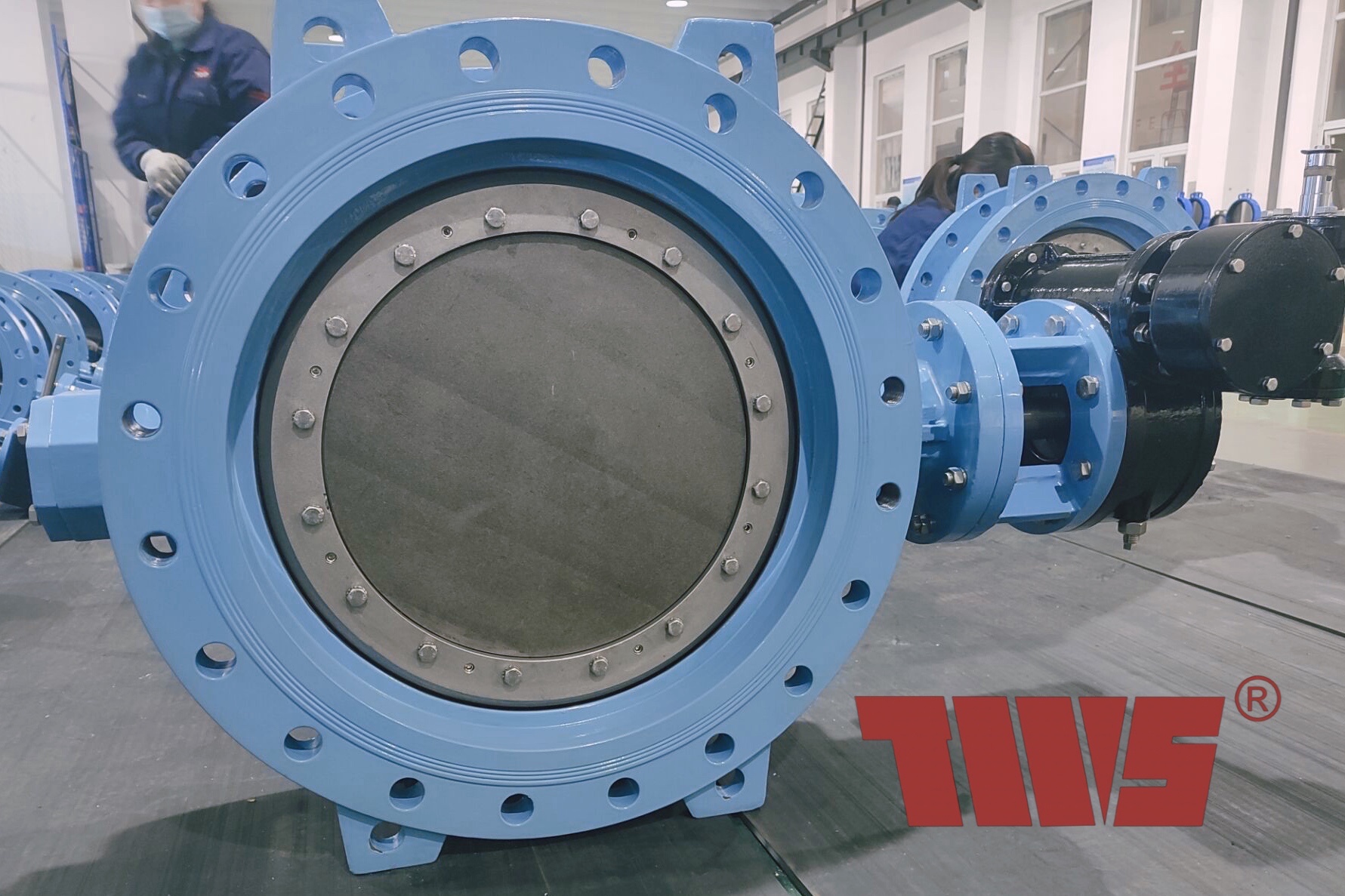

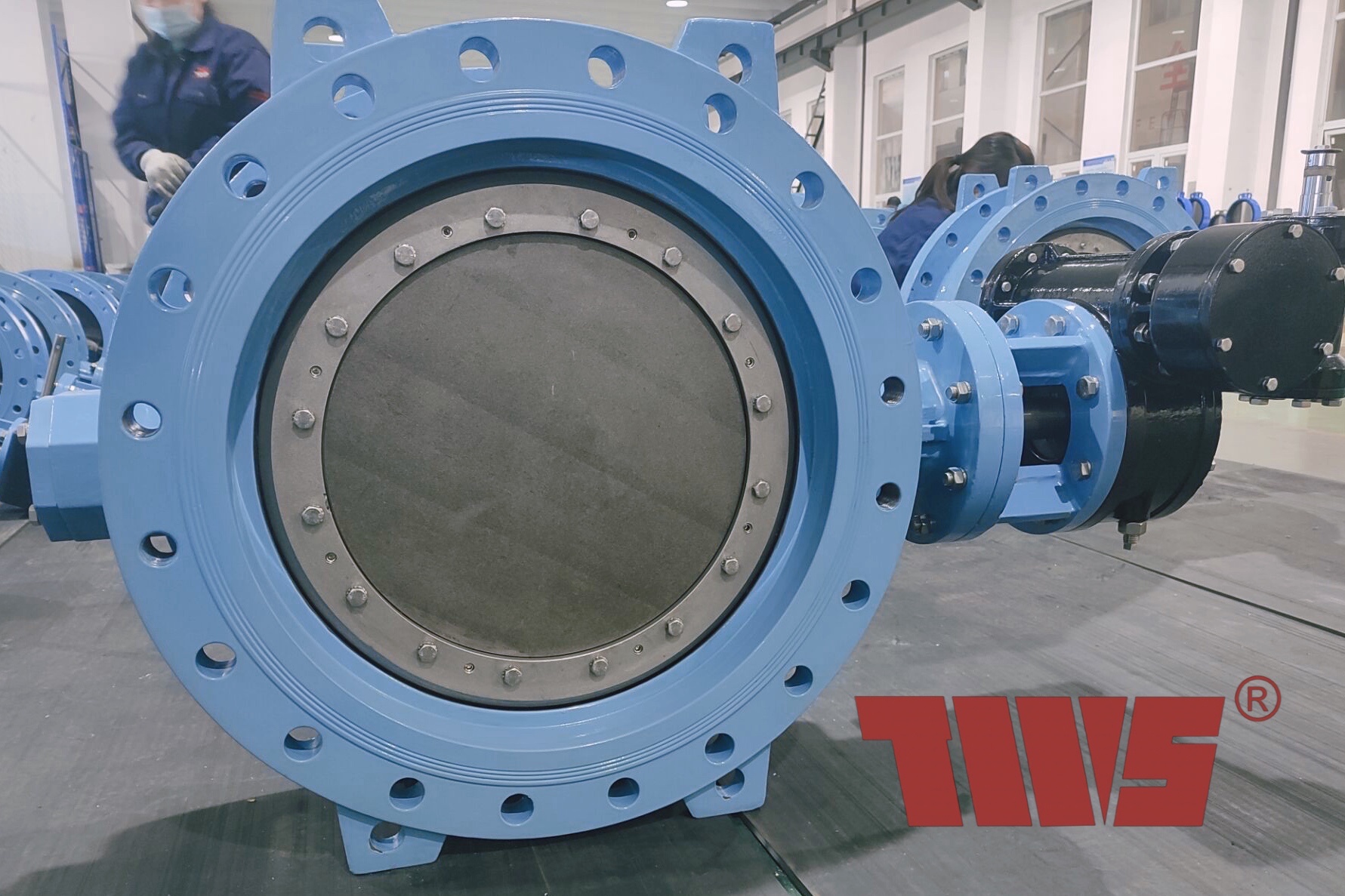

The working principle and construction and installation points of rubber seated butterfly valve

The rubber seated butterfly valve is a kind of valve that uses a circular butterfly plate as the opening and closing part and rotates with the valve stem to open, close and adjust the fluid channel. The butterfly plate of the rubber seated butterfly valve is installed in the diameter direction of...Read more -

How to maintain the gate valve with worm gear?

After the worm gear gate valve is installed and put into work, it is necessary to pay attention to the maintenance of the worm gear gate valve. Only by doing a good job of daily maintenance and maintenance can we ensure that the worm gear gate valve maintains normal and stable work for a long tim...Read more -

Introduction to the use, main material and structural characteristics of the wafer check valve

Check valve refers to the valve that automatically opens and closes the valve flap by relying on the flow of the medium itself to prevent the backflow of the medium, also known as check valve, one-way valve, reverse flow valve and back pressure valve. The check valve is an automatic valve whose m...Read more -

Operation principle and installation and maintenance method of Y-strainer

1. Principle of Y-strainer Y-strainer is an indispensable Y-strainer device in the pipeline system for conveying fluid medium. Y-strainers are usually installed at the inlet of pressure reducing valve, pressure relief valve, stop valve (such as the water inlet end of indoor heating pipeline) or o...Read more -

Sand casting of valves

Sand casting: Sand casting commonly used in the valve industry can also be divided into various types of sand such as wet sand, dry sand, water glass sand and furan resin no-bake sand according to the different binders. (1) Green sand is a molding process method in which bentonite is used ...Read more -

Overview of Valve Casting

1. What is casting The liquid metal is poured into a mold cavity with a shape suitable for the part, and after it solidifies, a part product with a certain shape, size and surface quality is obtained, which is called casting. Three major elements: alloy, modeling, pouring and solidification. The ...Read more -

What are the main factors affecting the sealing performance of butterfly valves?

Sealing is to prevent leakage, and the principle of valve sealing is also studied from leakage prevention. There are many factors that affect the sealing performance of butterfly valves, mainly including the following: 1. Sealing structure Under the change of temperature or sealing force, the str...Read more -

Why do stainless steel valves also rust?

People usually think that the valve of stainless steel and will not rust. If it does, it may be a problem with the steel. This is a one-sided misconception about the lack of understanding of stainless steel, which can also rust under certain conditions. Stainless steel has the ability to resist a...Read more -

Application of butterfly valve and gate valve under different working conditions

Gate valve and butterfly valve both play the role of switching and regulating flow in pipeline use. Of course, there is still a method in the selection process of butterfly valve and gate valve. In order to reduce the depth of soil covering of the pipeline in the water supply network, generally l...Read more